How Does a Pool Pump Work?

How Does a Pool Pump Work?

Pool Pumps are the heart of every swimming pool filtration system. Pool pumps are technically known as centrifugal pumps. They work on the principles of centrifugal force - water moving away from its center force. Pool pumps have both an inlet and outlet for water circulation.

The pump motor shaft powers the impeller, which spins the volute. This creates a high velocity of water. As the water is propelled toward the outer edge of the impeller, an area of negative pressure, or vacuum, is formed. Air must be exhausted from the system for a vacuum. The volute changes velocity as it creates energy. This action causes the water to flow through the filtration system plumbing.

What if the pump isn’t performing at full capacity? We recommend inspecting the O-rings and mechanical pump seal. These parts can disintegrate over time, causing air to leak and lowering the vacuum amount. The pump motor can also go bad after years of wear and tear. Luckily, replacing a motor is a lot more affordable than purchasing a new pool pump.

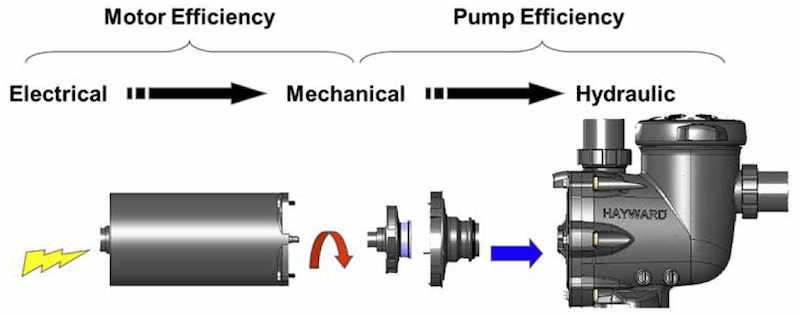

Pool pumps are a combination of an electric motor and a hydraulic “wet end”. The electrical energy is converted into mechanical movement when water is pushed through the rotating impeller. The “wet end”, aka hydraulic end, is where water channels into the pump before exiting to the filtration system.

FUN FACT! Pool Pumps don’t actually suck. Pressure in the “suction side” of the pump is lower than the atmospheric pressure, which “pushes” the water through the pump. This is the same principle as using a drinking straw.

Key Terms:

-

Motor Efficiency

How efficiently the motor converts an electrical current into mechanical movement when the motor shaft spins. The more efficient the pump, the less amount of electricity needed to do the same amount of work.

-

Pump Efficiency

How efficiently the pump parts channel and move water through the pump. If the wet end is efficient, less resistance is produced and less water flow is blocked as water moves through the pump.

-

Turnover Rate (TOR)

This is the amount of time it takes for the circulation system to move the number of gallons (equal to the volume of water in the pool) through the filtration equipment.

Now, let’s talk about the main parts of a pool pump:

Impeller

The impeller is the most important part of a pool pump. It is the only moving part of a pump. The impeller propels water at a very high velocity. Older pool pumps typically use a semi-open-face impeller. These are very inefficient and have low flow characteristics compared to energy-efficient pumps, which use closed-face impellers.

3 Types of Impellers:

- Open Face Impellers are used for trash and sewage pumps.

- Semi-Open Face Impellers are used in older pool pumps.

- Closed Face Impellers are the most energy efficient and easiest for lifting and priming. They have a higher flow rate (up to 50% more than open or semi-open faced impellers).

Pump Basket

The pump basket collects debris to protect the impeller from clogs and damage.

Pump Housing / Strainer

The strainer cover O-ring seals the strainer cover to prevent air from entering the the pump housing. All air must be exhausted for a pump to prime. Priming simply means re-establishing the water flow by a pump. Water is added to the pump/housing/strainer when the pump is turned on. As the impeller spins, it throws water over the edge and evacuates air in the process. This, in-turn, creates suction.

Pump Seal

The pump seal is also known as a mechanical seal. This ceramic and graphite device prevents water from leaking out of a centrifugal pump at the motor shaft. The seal is spring loaded to adjust for improper alignment and is water-cooled. It’s important to remember that the pump seal must never be lubricated or run dry. Pump seals and strainer cover O-rings are some of the most popular replacement parts for pool pumps.

What about the pump motor?

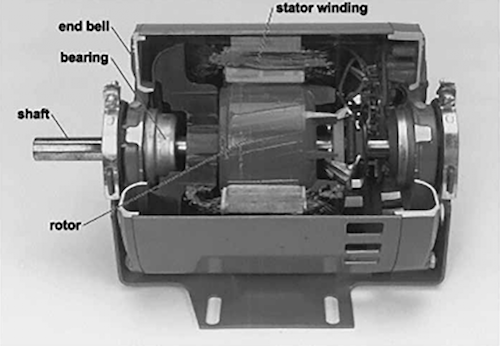

Here is a quick breakdown of the inside workings of a pool pump motor:

- The Shaft of the motor is attached to the impeller. The shaft spins, which in turn spins the impeller. This process accelerates the water drawn into the pump body before the water is pushed out of the return line.

- End Bells are also called End Shields or Cover Plates. End Bells are used to support the bearings or cover wingdings.

- The Bearing is responsible for allowing the motor shaft to spin smoothly in the correct position. The bearings are enclosed in a sleeve (bearing shield) to keep the bearing clean and spinning free. Ongoing leaks in the pump will corrode the bearings. Damaged bearings can result in decreased flow rate, an overheated pump or electrical damage.

- The Rotor and Stator Winding are responsible for alternating electrical current to turn the motor shaft. The Stator Winding produces a magnetic field with electrical current. The Rotor reacts to this magnetic field by creating torque and rotation.

There you have it! Everything you need to know about how a pool pump works and all of the parts needed to create water flow through your filtration system. To see our large selection of Single, Dual and energy-efficient Variable Speed Pumps, be sure to visit a local Leslie’s Pool Supplies or shop our convenient website today! Leslie's also offers FREE in-store labor. Let the experts take a look at the pump motor if you are experiencing any issues. We'll have your pool up and running in no time! Find your local Leslie's store HERE.

Additional Pool Pump Resources: