Hot Tub Covers and the R-Value Myth

The Myth of R-Value and Spa Covers

R-value is a measurement of the resistance to heat transfer for materials like the fiberglass insulation in your house or the insulating foam in our spa covers. In theory, the higher the R-value, the greater the heat retention and, heat retention is the primary function of any spa cover.

Most industries using R-values are regulated by FTC standards. Commercially sold insulation must pass independent tests created by American Standards and Testing Methods (ASTM) in order to be advertised or marked with their R-Value.

The Myth

As there is no FTC recognized independent test for spa covers, so any R-value stated by a spa cover dealer is actually an unregulated, unmonitored "interpretation" of the insulative value. It's open to speculation and abuse, from adding the R-value of the air space between the water and the cover, the space between the vinyl and the cover insulation, or simply blatantly inflating the number. At HTW, we state only the known R-value of the insulation itself plus a small increment for the vinyl and plastic wrapping the closed cell foam core.

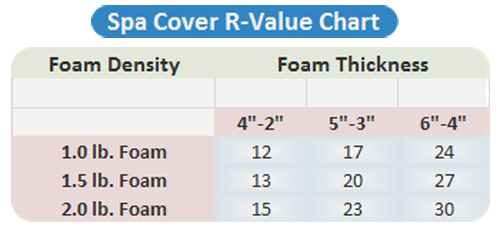

The R-value of the actual foam insulation plus covering in our Standard 1.5 lb foam covers is approximately 13.5 and for the denser 2 lb foam, it jumps to 15. This is based on an average spa cover thickness of 3"; our thicker spa covers will retain proportionally greater amounts of heat, as you can see in the image below.

Best Spa Cover Foam

Foam density and foam thickness are the two factors that affect the R-value of a particular spa cover.

It's easy to understand why a thicker and denser foam will reduce heat transfer. But the type of EPS (Extruded Polystyrene) can also make a difference. EPS is made from melting small pellets into a thick fluid, which is in then poured into molds and formed into sheets of varying thickness. The level of gas present in the mix, as well as mixing and drying methods can produce EPS foam of varying strength and density.

Our spa covers use the most expensive spa cover foam (rigid cellular polystyrene thermal insulation) available, which not only holds in more heat, but resists breakage, vapor absorption and chemical damage better than any other material we've tested.

ASTM C578 Type IV, 25 psi, 1.55 pcf Density

When shopping for and comparing spa covers, be leery of unsubstantiated claims of R-value. Look at Foam Density numbers and Foam Thickness. Most spa cover dealers should be around the same numbers. Our R-Values shown in the chart above are realistic, and in fact may even be higher, but the new EPS we now use has not yet been tested by the ASTM.

Myth Busted!

R-value testing of materials is done at room temperature, and doesn't take into account moisture and vapor. In the spa environment, we have hot water and lots of moisture. Both of these can facts will dramatically reduce the R-value of a material. Using the best quality EPS will almost prevent any moisture absorption, but a spa at 105 degrees will challenge the R-value of any material tested at 75 degrees.

Therefore, forsooth and verily I tell you ~ don't let R-value be your only measurement for spa cover quality, instead look for a spa cover with high density and weight, vacuum wrapped in continuous sheets of 6 mil heat welded polyethylene, sealed in heavy gauge marine grade vinyl, with chemical resistant scrim and stitching.